Guardex is a worldwide leading brand in the security inspection field, holding multiple patents in x-ray imaging and metal detection technologies. As maintaining security becomes an increasingly challenging endeavor, Guardex hopes to help its partners minimize and control this endeavor by deploying Guardex products and solutions to keep ahead of security risks through innovative, technologically advanced and high quality products and solutions.

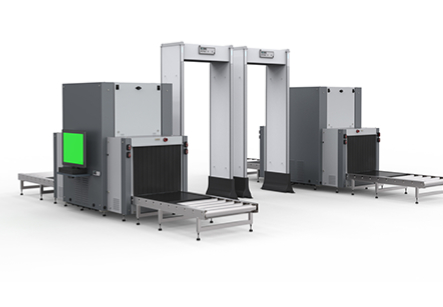

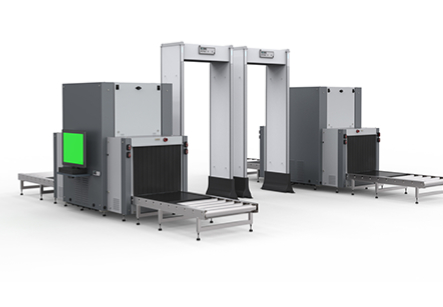

X-Ray IMAGING

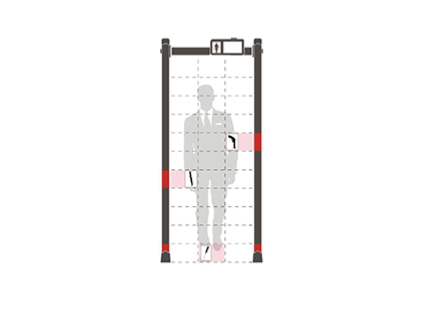

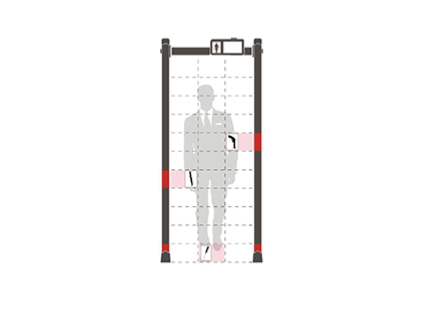

METAL DETECTION

METAL DETECTION  TRACE DETECTION

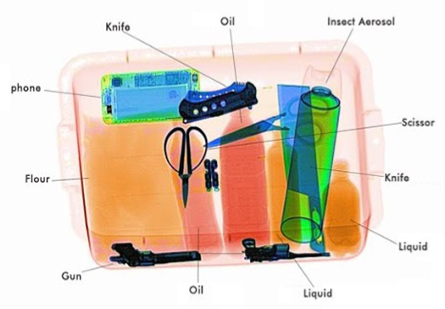

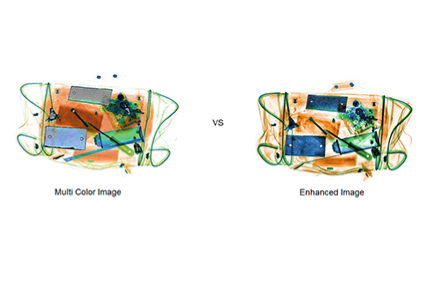

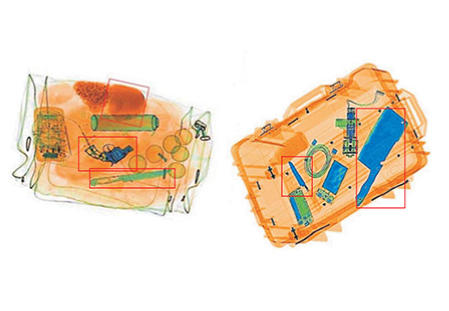

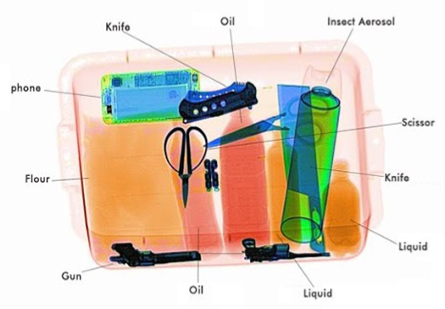

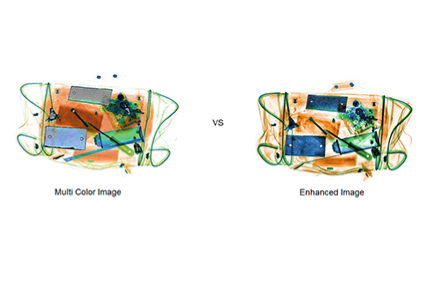

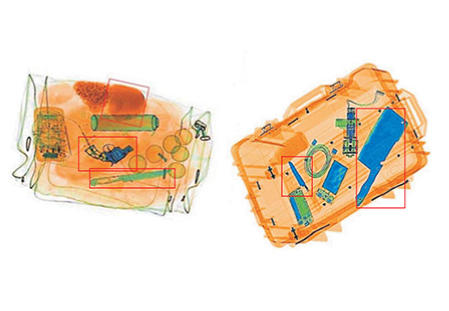

TRACE DETECTION To clearly identify the difference between Guardex and its competitors, we will start by explaining the basic operating principle of X-ray imaging; x-rays interact with matter, passing through it and being absorbed by the matter than scattering from it Matter with high density absorbs x-rays more than matter with low density, resulting in x-ray images being brighter where the rays pass through lower density matter and darker where the rays pass through higher density matter.

Trace detectors are detectors with the ability to detect tiny or `trace” amounts of explosive or narcotic residue or vapors. Trace detection can easily be divided into three types based on the whether the material being scanned had come in direct contact with the explosive or narcotic or not, Guardex has developed its trace detection products to be able to detect explosives and narcotics in both contact cases and even in case of being contained in non-contaminated barrier.

To clearly identify the difference between Guardex and its competitors, we will start by explaining the basic operating principle of X-ray imaging; x-rays interact with matter, passing through it and being absorbed by the matter than scattering from it Matter with high density absorbs x-rays more than matter with low density, resulting in x-ray images being brighter where the rays pass through lower density matter and darker where the rays pass through higher density matter.

Trace detectors are detectors with the ability to detect tiny or `trace” amounts of explosive or narcotic residue or vapors. Trace detection can easily be divided into three types based on the whether the material being scanned had come in direct contact with the explosive or narcotic or not, Guardex has developed its trace detection products to be able to detect explosives and narcotics in both contact cases and even in case of being contained in non-contaminated barrier.

Guardex

Address

5063 Commercial

Circle, CA 94520,

USA

Telephone

Email

+1 (650) 457 4580

info@guardex.org